DUE to the massive increase in industrialization in Ireland bringing quicker and cheaper production methods, many of the old trades and crafts which were prevalent in this area have now died out.

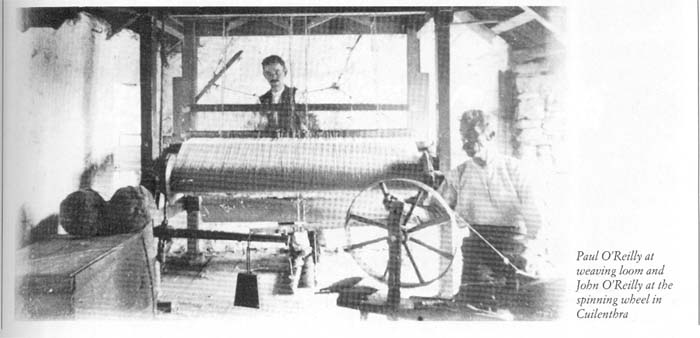

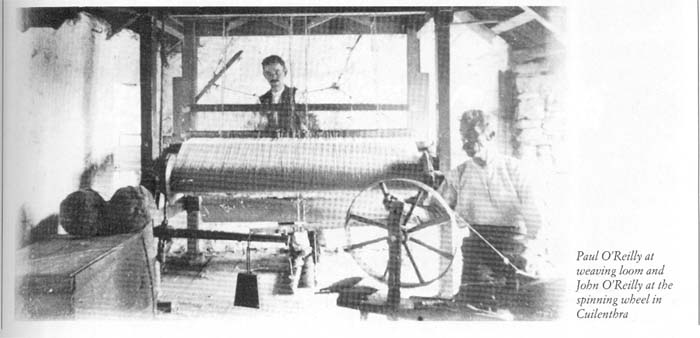

Spinning was one of the occupations of the woman of the house during the long winter evenings. The spinning wheel was common in homes within this area. The wool was first carded into long soft pieces, and a hard slender thread was made from them with the aid of a spindle. The threads were then rolled into a ball. The process of dyeing was enabled by boiling the wool with certain species of moss.

Most looms have the same basic features and weave fabric in the same way. Cloth is woven on a metal or wooden frame located at the front of the loom and parallel to the floor. The weaver must thread the loom before weaving. A set of warp threads are wound onto a cylinder called the "warp beam" at the back of the loom. Each warp thread is then passed through one of two or more vertical frame called "harnesses". The number of harnesses depends on the complexity of the weave.

Next the weaver winds the weft thread around a spool called the "bobbin" and the bobbin is held in an oblong metal or wooden container called the "shuttle". The shuttle serves as a needle that draws the weft thread over and under the warp. The weaver lifts the harness that holds the odd numbered threads. This action creates a space called the "shed" through which the shuttle and weft then pass.

Finally, the weaver lowers the first harness and pushes the newly woven row into place with a device called the "beater or reed." This beater is in a frame located in front of, and parallel to the harnesses. It has comb-like "teeth" made of steel wires that push each weft row compactly into place to tighten the weave. To weave the next row, the weaver raises the second harness and passes the shuttle through the "shed". The weaving of each row involves the same process.

Both spinning and weaving were popular occupations in the Newport area.